internal stresses in high temperature creep of metals|The mechanism of creep and its stages : retailer A new generalized creep constitutive relationship containing four stress-dependent parameters and creep time can describe various complicate creep curves of high .

web5 horas atrás · A previsão é válida até às 10h de sexta-feira. O Rio de Janeiro terá muitas nuvens com pancadas de chuva e trovoadas isoladas a partir da tarde nesta sexta-feira. .

{plog:ftitle_list}

I migliori casino non AAMS che accettano nuovi giocatori italiani. Il mondo dei siti non AAMS è davvero variegato ed è facile intuire, quindi, che ci si possa sentire disorientati nella scelta di un casinò a cui affidare il proprio divertimento ed i propri soldi. Il primo passo da fare, come già accennato, è quello di verificare la .

Internal and effective stresses in high-temperature creep evaluated from transient dip tests and dislocation bowing. JOURNAL OF MATERIALS SCIENCE 27 (1992) 4365-4372.

gypsum block moisture meter

When polycrystalline metals and their alloys are used at high temperature, creep deformation leads to changes in their internal state. The change in internal state manifests itself in many . High-temperature creep tests of additively manufactured (AM) and wrought nickel alloy 718 (IN718) were conducted at 650 °C and 704 °C at stresses ranging from 316 to 819 . Creep of crystalline materials at high temperatures is a thermally activated process and is governed by the mobility of point or line defects. Shear or sliding in the grain .

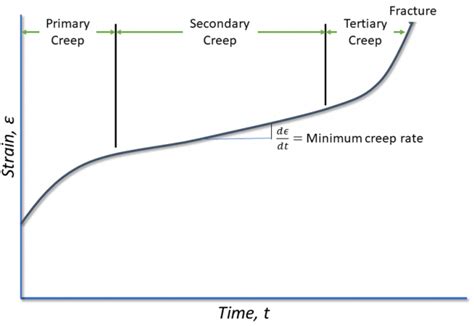

The mechanism of creep and its stages

Creeps are characterized as time-dependent permanent deformations that occur under constant stress at elevated temperatures. The material composition determines the onset of creep. For example, steel . A new generalized creep constitutive relationship containing four stress-dependent parameters and creep time can describe various complicate creep curves of high .

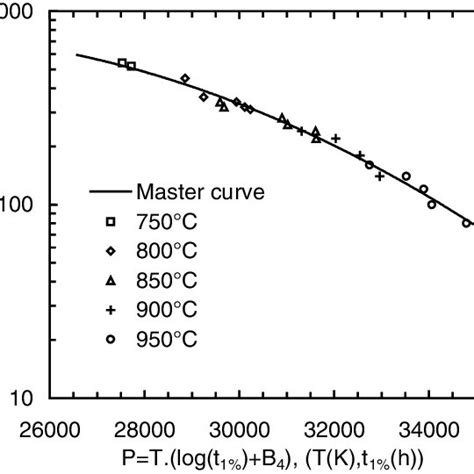

P92 steel is widely used in ultra-supercritical units due to its excellent high-temperature performance. This paper studies the microstructure of P92 steel steam pipes in . At higher temperatures and lower stresses, diffusion creep becomes the dominant mechanism. Nabarro [4] and Herring [5] proposed that the creep process was controlled by stress-induced diffusion. Experimental techniques used to measure the internal stress and internal resistance over different length-scales are critically reviewed. It is demonstrated that the .Article An Interpretation of the Internal Stress Measured by a Transient Dip Test in High-Temperature Creep of Metals was published on January 1, 1974 in the journal International Journal of Materials Research (volume 65, issue 1).

The high temperature creep and fracture behavior of Inconel 718

Microstructural Evolution of P92 Steel with Different Creep Life

Recovery-Creep Models and Internal Stress As early as 1926, Bailey (1926) proposed that creep resulted from recovery of the strain-hardened state. Orowan (1946-1947), twenty years later, applied this concept in his discussions on the origin and nature of creep. . The apparent activation energies for high-temperature creep of metals and dilute .

Work-hardening rates during the high temperature creep of magnesium determined from the instantaneous strain on sudden stress changes . Materials Science and Engineering A 462 (2007) 215–219 Internal stresses during creep of magnesium alloys at 523 K Karel Milička a,∗ , Zuzanka Trojanová b , Pavel Lukáč b a b Institute of Physics of .

The high-temperature deformation behavior of an additively manufactured Al-Cu-Mn-Zr alloy is evaluated in the as-fabricated and heat-treated states using traditional ex-situ and in-situ neutron diffraction creep experiments performed at 300 °C. The dominant reinforcement phase in the alloy, θ-Al 2 Cu, despite its high volume fraction of ∼10%, does not provide load .

Recent progress in the understanding of high-temperature creep of alloys is discussed in the context of theoretical modeling and its application to alloy development. Emphasis is placed upon those engineering alloys specifically designed for high-temperature applications, such as precipitation and dispersion-strengthened (DS) alloys and metal-matrix composites (MMCs). .At extended periods of high temperature and stress, creep can cause metals to deform excessively and eventually fail. This failure can evolve in several ways. . in the crystal structure of the metal. During the initial stages of creep, dislocations move and multiply, creating internal stress within the metal. As more and more dislocations .DOI: 10.1016/0022-3115(88)90152-3 Corpus ID: 96855089; Internal stress during high-temperature creep of special grade hastelloy X alloys @article{Kurata1988InternalSD, title={Internal stress during high-temperature creep of special grade hastelloy X alloys}, author={Yuji Kurata and Yutaka Ogawa}, journal={Journal of Nuclear Materials}, year={1988}, . The deformation mechanisms involved in the tensile creep of a Ti 3 AlC 2 specimen deformed, at 900 °C, to a 7.5% final strain are investigated through SEM and TEM observations. Tensile creep strain rate analyses on Ti 3 AlC 2 deformed at 900 °C enabled to identify a Norton's law with a n coefficient around 2, suggesting that creep mechanisms are controlled by grain .

Creep tests and the measurement of internal stress during creep were performed at 900°C for Hastelloy XR and XR-II, i.e. versions of Hastelloy X modified for nuclear applications. Creep rupture time and steady-state creep rate were influenced by the boron content, grain size and heat-treatment temperature of the alloys.Observations of anelastic backflow following stress reductions during creep of pure metals. J. Gibeling W. Nix. Materials Science. 1981; 97. . effective and internal stress in high-temperature creep of alpha iron. . Recent experimental work indicating the existence of a friction stress, σ0 during high temperature creep is reviewed.

High-temperature X-ray line profile measurements were performed to maximal temperatures of 1050 °C on samples of the nickel-base superalloy SRR 99. The samples with rod axes near the [001] direction were investigated in the initially undeformed state and after creep deformation at different temperatures and stresses. For the measurements of the (002) and (020) line . Download Citation | The Role of Long-Range Internal Back Stresses in Creep of Metals | Description This publication of 24 technical papers that utilize an interdisciplinary approach to deformation .

A review of the changes of internal state related to high temperature creep of polycrystalline metals and alloys . such as Al13 and other FCC metals,40 BCC metals40 and HCP metals,41 a creep stress exponent of n close to 5 is often obtained. Creep data for pure Al with n54?6 are shown in Fig. 2a. It is well established that a stress exponent . 2. Creep • Creep is a time-dependent process where a material under an applied stress exhibits a dimensional change at high temprature. • High temperature progressive deformation of a material at constant stress is called creep. • The process is also temperature-dependent • Creep always increases with temperature. The internal stress σ i was measured with strain transient dip tests in ordered and disordered beta brass during high temperature steady state creep. The normalized internal stress σ i σ, where σ is the applied stress, in both ordered and disordered beta brass is small at the larger stress levels.This result agrees well with our theory of internal stress for class I .

The high temperature properties of wrought materials of uniform composition are different from those of materials exhibiting compositional fluctuation, which is generally caused by differences in materials processing.

Internal and effective stresses in high

The present knowledge and ideas on the dislocation substructures in high temperature creep of metals and solid solution alloys are reviewed with special reference to contributions that appeared in the last decade. . and contemporary ideas of the relation of substructure to long-range internal stresses are outlined. Knowledge of the .A review of the changes of internal state related to high temperature creep of polycrystalline metals and alloys Peter E J Flewitt 2014, International Materials Reviews A survey of experimental studies of a relation between dislocation structure and internal stress σ i measured by means of the strain transient dip test technique in high temperature (mostly steady-state) creep of various metals and single phase alloys is given. Application of various approaches, i.e. direct evaluation of σ i from quantitative structure data, .There are two significant interactive contributions to the creep lifetime of engineering materials, i.e. creep deformation and creep fracture. 4 Materials may deform by several different mechanisms when subjected to an applied stress at high temperature, and it is convenient to present these mechanisms in the form of a deformation mechanism map. 5,6 Similarly, .

In this overview on the high temperature creep resistance of austenitic heat-resisting steels, the main focus is on the creep resistance rather than on the rupture strength. . The effect on internal stress is also summarized. As to the precipitation strengthening, commer- cial heat-resisting austenitic steels are usually dis- 0921-5093/91/. .

High temperature creep deformation can be characterized in terms of internal and effective stresses. In this approach, the mean internal (back) stress, 0i, provides the driving force for recovery .Article An Interpretation of the Internal Stress Measured by a Transient Dip Test in High-Temperature Creep of Metals was published on January 1, 1974 in the journal International Journal of Materials Research (volume 65, issue 1).The coupling of cross-slip and climb controlled recovery processes leads to gradual transitions in strain hardening and gives a natural account of the transition from low temperature deformation to high temperature creep. The model also leads to polarized dislocation structures, internal stresses, and anelastic creep properties.

• Restructuring of atoms also occur at high temperature. • Movements of dislocations also more likely at high temperature through diffusion. Creep is dangerous as an unanticipated failure could prove fatal. Typical creep rate: Jet engine: 1% in 10,000 hours. Steam generator: 1% at 100,000 hours. Special test required!!!!! To evaluate .Journal Article: Interpretation of the internal stress measured by a transient dip test in high-temperature creep of metals. Interpretation of the internal stress measured by a transient dip test in high-temperature creep of metals. Full Record; Other Related Research; Authors:FULL CRITICAL REVIEW A review of the changes of internal state related to high temperature creep of polycrystalline metals and alloys B. Chen*1{, P. E. J. Flewitt2,3, A. C. F. Cocks4 and D. J .

Creep Fundamentals

webIlustrações . Fundos . Texturas . Padrões . Cartoons . Clip art . Desenhos . Símbolos e sinais .

internal stresses in high temperature creep of metals|The mechanism of creep and its stages